| > E&O/GL Insurance for Home Inspectors Competitive Rates, Broad Coverage, Free Risk Management, online inspection support for tough questions, discounts on education and more... Professional Coverage, Competitive Pricing Shop OREP today! |

>> Editor’s Note: To help you stay up-to-date and connected, OREP/Working RE has established a Coronavirus (COVID-19) Discussion and Resource Page where you can share your thoughts, experiences, advice and challenges with fellow inspectors. See what Inspectors are saying here!

On Again, Off Again: Understanding Well Pump Systems

The Science Behind Your Inspection

by Tom Feiza, Mr. Fix-It, Inc. HowToOperateYourHome.com

Private wells and well pump systems are beyond the scope of many home inspectors, but we all should understand the basic science behind submersible pumps, well pressure tanks, controls, and typical private well systems. Inspectors should know how to recognize a short-cycle pumping problem often called a “water logged” tank.

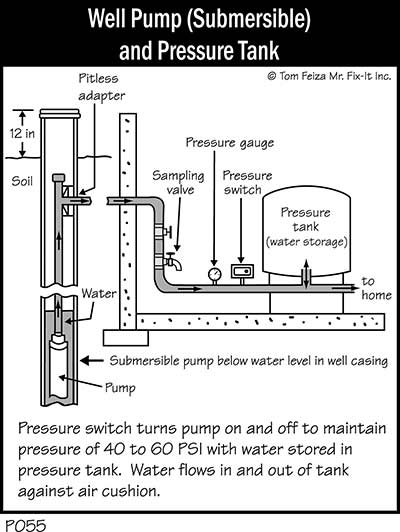

Typical Submersible Pump System

Under normal conditions, a private well system utilizes a submersible centrifugal pump immersed in water near the bottom of the well casing (See Figure 1). The pump lifts and pushes water through a pipe in the well casing and then through an underground pipe into a storage/pressure tank in the home. The pump is hung from the vertical pipe and the pitless adapter on the side of the casing. The pump can be “pulled” from the casing on the pipe and disconnected from the adapter. Today the pipes are often plastic.

During an inspection you may see the well casing outside and it should be at least 12 inches above the soil to prevent contamination. The cap on the casing should also be a gasketed/sealed cap as shown (See Photo 1). On the side of the casing, you can see the electrical conduit for the 240V electrical to the pump. The pressure/storage tank, pressure controls, pump control, gauge, and sampling valve will be located inside the home.

Some of these systems are located in exterior pits or sheds but that is not common. The tank and piping must be protected from freezing conditions. There are also shallow well systems with “jet” pumps that sit on top of the casing—again not a common system.

Figure 1: Well Pump (Submersible) and Pressure Tank

Photo 1: Private Well Casing

Photo 2: Modern Pressure Tank

Typical Pressure Tank and Well System

The storage tank or pressure tank limits the cycling of the pump by storing water and maintaining a cushion of air over stored water or air over a rubber bladder containing water (See Photo 2). The picture shows a typical, modern, blue, pressure tank in a basement. The small gray box on the side of the tank is the pressure switch/control that monitors the pressure in the tank and switches the red relay box on the wall providing electrical current to the pump. Modern tanks are also made of fiberglass.

There are shut-off valves and a sampling valve. On the left side of the tank, the pipe from the well casing enters the basement. In this case, there is a casing visible—often there is just a copper or plastic pipe through the wall. The electrical wiring also feeds through the casing on the wall. The bond from the main electrical panel is connected on both sides of the tank because there is a rubber (non-conducting) vibration isolator in the pipe to the well.

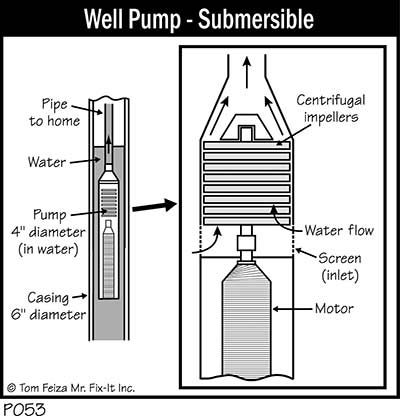

Outside, well systems typically have a six-inch steel casing placed in a hole drilled down to the water table. Inside this casing is the small four-inch diameter pump and motor (See Figure 2). The pump has a 240V volt motor directly connected to a series of impellers. On a call for water (low pressure in the tank), the motor spins the impellers to create sufficient pressure to push water up into the storage tank, compressing the air in the tank. The pump and tank design are matched to the quantity of water desired and the depth of the well.

Storage Tank / Pressure Tank Types

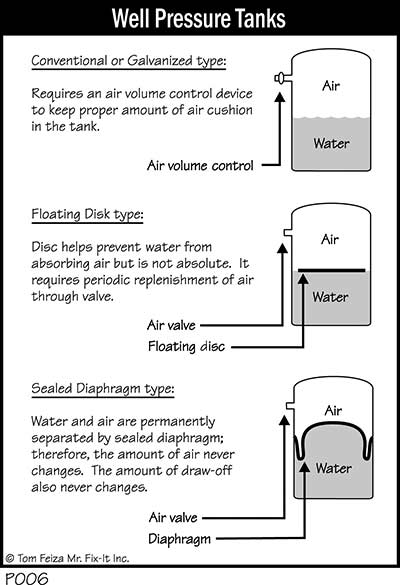

There are three basic types of well pressure/storage tanks as shown in the illustration (See Figure 3).

Figure 2: Well Pump – Submersible

Figure 3: Well Pressure Tank

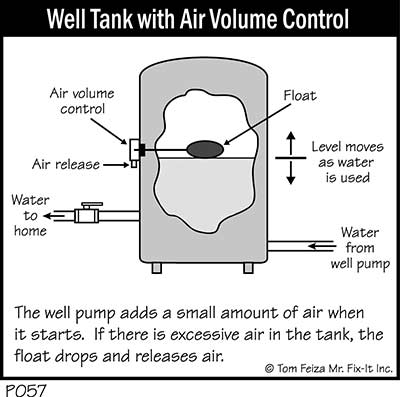

Figure 4: Well Tank with Air Volume Control

Conventional Tank

This older style tank is an air over water tank and normally galvanized steel. Some also include a system on the pump that adds a little air every time the pump starts—those have an air release for excessive air (See Figure 4). When there is too much air, the float drops and releases air. With an air volume control, you will often see a rusty/damp area on the side of the tank below the air release. It will look like the tank periodically leaks.

This type of tank is used today when there are contaminates in the water that cause that rotten egg smell. They reduce the smell in the water by allowing water to be in contact with air in the tank.

Floating Disk Tank: This is a galvanized steel tank with a floating disk to limit the loss of air into the water. When there is a direct air/water interface, air is lost into the water. With this tank, the air/water contact is limited by the floating disc.

Sealed Diaphragm Tank: This is normally a blue painted steel tank (See Photo 2). This type includes a complete separation of the air/water with a rubber bladder. However, the rubber bladder can fail and allow this type of tank to lose the air cushion.

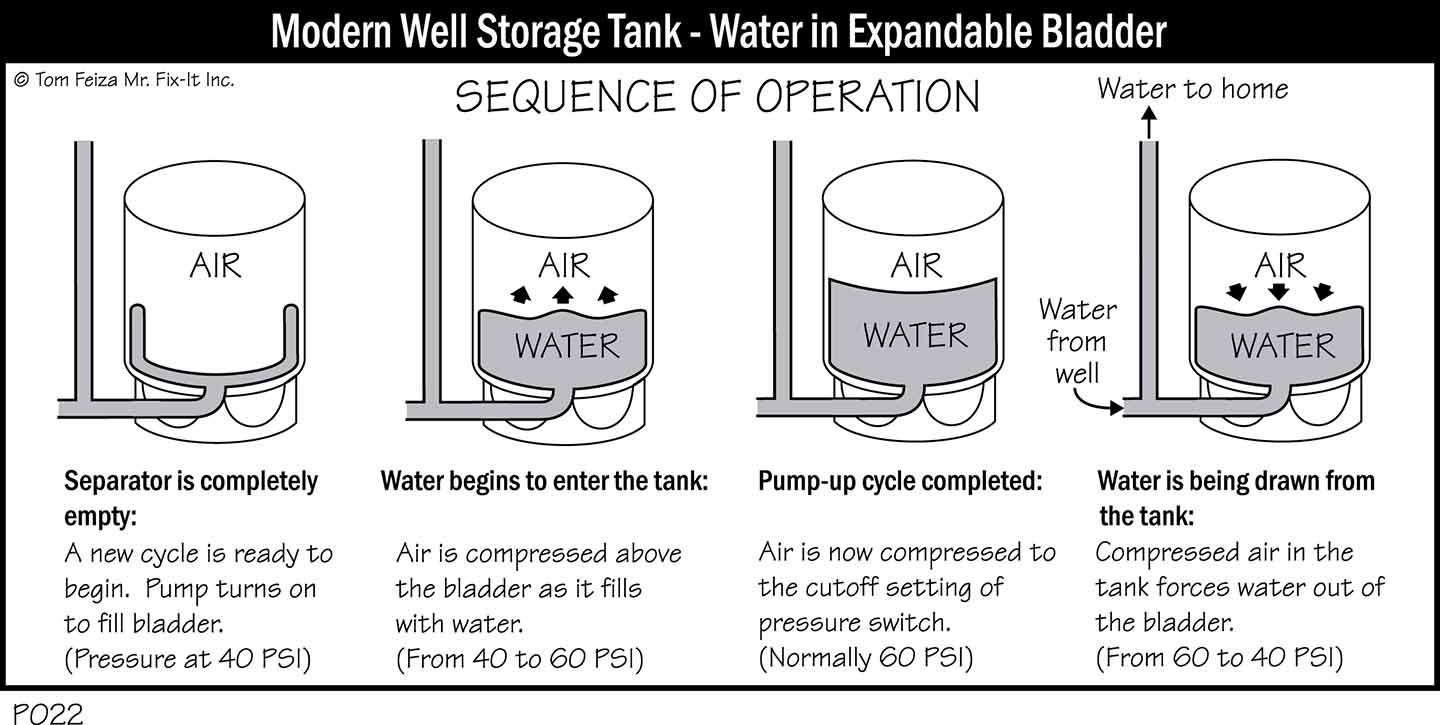

Water Use Triggers System: When someone in the household draws water, air expands in the tank, pushing water out into the system. This reduces air pressure in the tank (See Figure 5). As pressure in the tank approaches 40 psi, the pump switches on, refilling water in the tank and restoring the air pressure. When the air is compressed to about 60 psi, the pump turns off. This operation allows the home’s water flow to remain almost constant, as the 20 psi pressure change is rarely noticeable.

The pump is controlled by that gray pressure switch located on the pressure tank. Systems typically run between 40 and 60 psi but can be set to a higher or lower pressure. Often, pressure is set with a simple spring and screw adjustment inside the pressure switch housing. This also means the pump does not run every time water is used. The pump will cycle on after a quantity of water—perhaps three gallons, is used. This limits the start-stop cycle of the pump.

(story continues below)

(story continues)

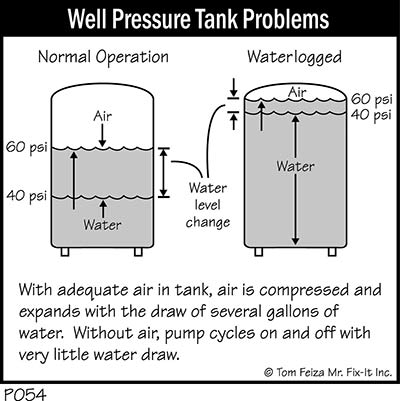

Loss of Air Cushion Causes Problems: Problems occur when the system loses its air cushion (See Figure 6). In systems with no bladder, air is simply lost through contact with the water, with the air cushion disappearing over a period of several months. Some systems have a floating disk that slows the loss of air. Air loss can also occur with rubber bladder systems when the bladder fails.

When there’s little air in the tank, the system kicks in repeatedly whenever someone draws as little as a quart or even cup of water. The pressure switch clicks on-off-on-off and the pump turns on and off. With the pressure fluctuating so quickly, noticeable changes occur in flow and pressure. This “short-cycling” will eventually damage the pump.

Other Private Well Systems: Some shallow well systems have a “jet” pump that sits on top of the shallow well casing. These are often found in areas around lakes. Some older systems have a deep well jet pump that has two pipes in the water that inject water to create pressure. These systems also rely on a pressure tank to even the water pressure and flow—and limit cycling the pump.

In recent years, sophisticated systems have become available, providing a variable-speed pump to vary the flow/volume of water; these eliminate the pressure tank or use a very small pressure tank. They depend on a complicated control and pump system.

Figure 5: Modern Well Storage Tank – Water in Expandable Bladder

Figure 6: Well Pressure Tank Problems

What Home Inspectors Should Know

If you run water during a home inspection and notice quick variations in pressure/flow or you can hear the pump quickly cycling on-off-on-off, you should note this as a potential issue to be evaluated by a specialist. I like to run water in a fixture near the pressure tank and listen for the well cycling. In this case, you are not doing a private well inspection but simply pointing out obvious issues that need further evaluation. Whenever there is a private well system, you should recommend further evaluation by a specialist and water testing for possible contamination.

Also know local municipal health departments often require routine testing. Health departments also require abandoned wells to be properly closed and sealed to prevent contaminates from entering the water table. Normally private wells must be fully operational and tested and you should note the caution in your report for further evaluation. If you find a well system that is not being used, that needs to be reported for further evaluation. Well casing in pits and basements is often not allowed without special pit drainage systems.

About the Author

Tom Feiza has been a professional home inspector since 1992 and has a degree in engineering. Through HowToOperateYourHome.com, he provides high-quality marketing materials, books for homeowners, and illustrations that help professional home inspectors educate their customers. E-mail Tom (Tom@htoyh.com) with questions and comments, or phone (262) 303-4884. Copyright © 2021 by Tom Feiza, Mr. Fix-It, Inc. Reproduced with permission. Visit Htoyh.com for more information about building science, books, articles, marketing, and illustrations for home inspectors.

OREP/WRE Coronavirus Discussion and Resource Page

Coronavirus: National Home Inspector Survey

Real-Life Inspector Lawsuits and How to Protect Yourself

Available Now

Presenter: Isaac Peck, President of OREP

Isaac Peck, President of OREP Insurance Services, shares his insights and advice gained over nearly 10 years of providing risk management and E&O insurance for home inspectors. You will not hear many of these insights anywhere else.

Watch Now!

Note: The Fall 2021 Working RE Home Inspector is mailing now to over 25,000 home inspectors nationwide. OREP Insureds/members enjoy guaranteed delivery of each print magazine and many more benefits.