|

> E&O/GL Insurance for Home Inspectors Competitive Rates, Broad Coverage, Free Risk Management, online inspection support for tough questions, discounts on education and more… Professional Coverage, Competitive Pricing Shop OREP today! |

Radon Testing: Myth of the Ideal Radon Device

By by Shawn Price, Director of Laboratory Operations (AccuStar Labs), Spruce Environmental Technologies, Inc.

In my many years in the radon industry—I won’t say how many —suffice it to say that I was a member of the group that developed the first EPA radon proficiency program and created the program to evaluate new radon measurement devices, I have observed that, even among professionals, the myth of the ideal radon device continues.

Some facets of the myth are:

• The more complex the radon device, the better it is.

• The more expensive the radon device, the better it is.

• The longer the radon device tests, the better it is.

• The best radon testing device is ________ (Fill in the blank).

The fact is that all radon devices have strengths and cautions. All depend on how well or poorly the tester uses them.

Only Use Listed Test Devices

To perform radon testing in the field, it’s critical to use a device that is approved by a national agency. These are the two agencies that certify radon professionals and devices: National Radon Proficiency Program (NRPP) and National Radon Safety Board (NRSB). The goal for the device when performance testing is +/- 25%. ALL devices must meet that goal.

To achieve a device listing:

• All listed devices must be chamber-tested.

• All must meet requirements to be used in field.

Accuracy = Precision and Bias

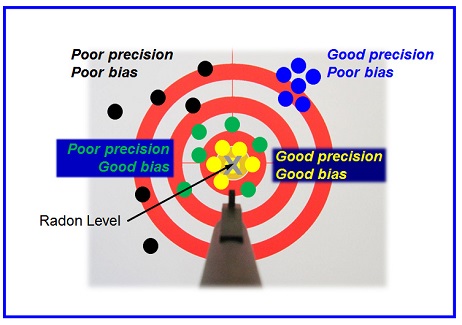

• Good precision is like having a good “group” of shots. That is, everything is consistent…but it can be off target.

• Good bias is when the average of a group is close to the bullseye…but some hits may be off the mark.

How can you know you have “hit the bullseye?” In Figure 1 above, you can see that the navy blue and the yellow dots have good precision: the measurement results are very close to each other. But the blue dots are not accurate. We need another measure. “Bias” tells us whether the calibration process was done correctly, if contamination has gotten into the system, or if there is another systematic problem that can repeatedly skew the results high or low. While the goal is to hit the bullseye every time, the reality is that measuring radioactive materials is an errorprone process. If devices are calibrated properly, we should have some measurements slightly above and slightly below the target. Always missing on one side of the target is an indication of poor bias, as shown with the blue dots. The green dots have good bias: if you added them all up, they would be right on target. However, they have poor precision, so they’re not accurate either. We need to have BOTH good precision and good bias to tell us whether our device is reading what’s there. We might compare precision and bias measurements, in our car analogy, to checking our speedometer by having another car drive next to us at a certain speed, or checking the exhaust with a device that measures some contaminants or using a timing light and so on.

(story continues below)

Accuracy Based on Following Directions

If you follow the manufacturer’s directions explicitly, you should receive good enough data to help the client make a good radon decision. THAT IS THE point of the test: To mitigate or not to mitigate?

Know Your Device

The most important thing you can do to get good radon readings is to KNOW YOUR DEVICE and follow the manufacturer’s instructions.

Common Radon Devices

Electret Ion Chambers consist of an electrically conductive chamber attached to an electret, a Teflon plate that is positively charged. Negative ions produced from the decay of radon reduce the voltage on the electret. This change in voltage over time is used to calculate the radon concentration.

Charcoal Canisters use activated charcoal to adsorb radon. The charcoal canisters can then be counted using gamma spectroscopy to determine the radon concentration.

Liquid Scintillation Vials use activated charcoal to absorb radon as well but then use a different analysis process. After exposure, a “cocktail” is added to the vial which fluoresces when radioactive decay occurs. These light pulses can then be used to determine the radon concentration.

Alpha Tracks use a certain type of plastic that is sensitive to alpha particles. When an alpha particle hits the surface of the plastic, the alpha particle leaves a track. The plastic is then soaked in a caustic solution to enlarge the tracks. When put under a microscope the tracks are counted and used to determine the radon concentration.

Continuous Monitors use several different types of technology, like solid state detectors, alpha scintillation or ionization chambers, to determine the radon concentration. Continuous monitors are the only type of device that gives an hourly average of the radon concentration.

Free Risk Management Online Course Claims and Complaints: How to Stay Out of Trouble

Available Now

Presenter: David Brauner, Senior Insurance Broker OREP

David Brauner, Senior Broker at OREP, shares insights and advice gained over 25+ years of providing E&O insurance for inspectors, showing you how to protect yourself and your business. Watch Now!

About the Author

Shawn Price has 28 years of radon industry experience and is currently the Director of Laboratory Operations for the AccuStar Labs Division of Spruce Environmental Technologies, Inc., Price is also the Past-President of the American Association of Radon Scientists and Technologists (AARST), and a member of the National Radon Proficiency Program (NRPP) Policy Advisory Board.

Note: The Winter 2019 issue of Working RE Inspector mailed to over 20,000 home inspectors nationwide. OREP Insureds enjoy guaranteed delivery of each print magazine and many more benefits.

OREP Appraiser E&O insureds enjoy it free and this year Free Approved Continuing Education!!