|

> E&O/GL Insurance for Home Inspectors Competitive Rates, Broad Coverage, Free Risk Management, online inspection support for tough questions, discounts on education and more… Professional Coverage, Competitive Pricing Shop OREP today! |

High-Efficiency Forced Air Furnaces: Science Behind Your Inspection

by Tom Feiza, Mr. Fix-It, Inc. (www.htoyh.com)

Homeowners today can enjoy the luxury of high-efficiency forced air furnaces. They are quieter, less expensive to operate and capable of providing stable temperature throughout the home.

It wasn’t that long ago—from roughly 1920 to 1980—that the naturally drafted gas furnace was king. It operated at about 50% to 65% efficiency. With the flue gas maintained at about 350 degrees Fahrenheit, steam and products of combustion went right up the masonry chimney and there were no condensation problems. The steam looked like smoke as it wafted from the chimney.

You could recognize this 60% furnace by its metal flue pipe and a draft diverter or draft intake. From a distance the home looked great, but up close these problems were evident (See Figure 1: Naturally Drafted 60% Gas Furnace).

Figure 1: Naturally Drafted 60% Gas Furnace

Burners were exposed at the bottom of the heat exchanger, and combustion air was drawn from the room into the burners. Controls were electro-mechanical, not digital. With this furnace drafting warm air up the chimney and transferring only about 60% of the natural gas energy into the home, much of the energy was wasted.

When energy costs increased dramatically in the 1980s, energy shortages were predicted. Incremental improvements in efficiency came into the market: flue dampers, electronic ignition, better heat exchangers and new control systems.

Condensing Furnace: One Giant Leap in Efficiency

Later came high-efficiency condensing furnaces, with dramatic improvements in efficiency (See Figure 2: 90% Condensing Gas Furnace). Note that there is no metal flue pipe; instead, there are two PVC pipes, one that delivers air for combustion into the furnace and one that exhausts the products of combustion away from the furnace. As its name implies, this furnace delivers about 90% of the combustion energy into the home. There’s significantly less heated air going up the chimney than there was with the older models.

Today’s condensing furnaces use a secondary heat exchanger. It captures more heat by lowering the temperature of the flue gas from 350 degrees Fahrenheit to about 120 degrees and condensing the steam into water. A drain line removes the condensation water away from the heat exchanger and burner assembly.

Figure 2: 90% Condensing Furnance

A Furnace by Any Other Name…

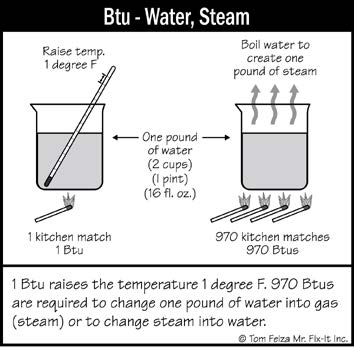

A high-efficiency furnace is better described as a “condensing” furnace because it condenses steam in the flue gas to grab more Btus. A Btu is a unit of heat equivalent to burning one kitchen match (See Figure 3: BTU – Water, Steam). One Btu raises the temperature of one pound of water 1 degree Fahrenheit.

It takes 970 Btus to bring one pound of water to a boil. Think about cooking noodles in boiling water: the water is heated to about 212 degrees Fahrenheit and then begins to boil as the heat accumulates. Add more heat and the water just boils; the temperature does not increase. When you reverse the process and “condense” a pound of steam into water, 970 Btus transfer into the air. The energy necessary to change the phase of the water/steam is called latent heat.

The furnace pictured here is 96% efficient (See Figure 4: 96%, Three State Gas Furnace). It provides three controls and three firing rates. Its ECMs (electronically commutated motors) spin at a variable rate, providing greater efficiency and better comfort as well as substantial savings on electrical power. When firing at a lower rate, efficiency is improved and fan noise is reduced. The unit runs longer per heating cycle and provides greater comfort in the home.

Figure 3: BTU – Water, Steam

Figure 4: 96%, Three Stage Gas Furnace

(story continues below)

With this furnace, 96% of the energy remains in the home and only 4% goes up the chimney. The “chimney” is the PVC pipe to the outside. Notice the draft or inducer fan in the picture—it draws in combustion air and expels the products of combustion to the outside. The three control pressure switches (tagged 1-2-3 in the picture) provide safety switching for three firing rates. When you see three pressure switches, you know the furnace has three firing rates.

Getting Down to Details

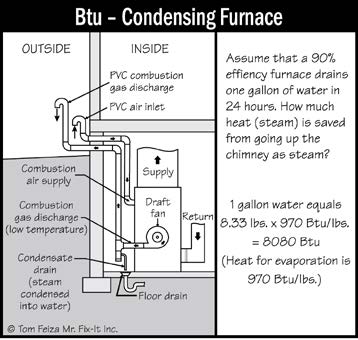

Here’s a detailed view of what’s going on (see Figure 5: BTU– Condensing Furnace). Condensing steam captures the latent heat—that is, heat from the change of phase from steam into water—at a rate of 970 Btu per pound of water (steam). If a furnace uses about one therm of natural gas per hour (100,000 Btu/hr), that combustion creates about one gallon (8.33 lbs) of water. We capture 8,080 Btu per pound of steam by condensing it back into water in the secondary heat exchanger. In a larger home, we could capture ten times that amount of energy over 24 hours. Furnace efficiency has increased from 60% to more than 90% when steam is condensed.

ECM motors with sophisticated electronic controls also adjust the volume of air movement through the system and can allow the firing rate to change. The blower will match the burner output. In systems with zoned air delivery, the ECM variable- speed blower matches the flow to the zones calling for heat or cooling. This eliminates the need for an air bypass on the ductwork.

Figure 5: BTU – Condensing Furnace

Condensation Issues Resolved

Initially, the heating industry had lots of issues related to the slightly corrosive condensate water in the heat exchangers and the burner assembly. Designers, manufacturers and repair workers had never dealt with corrosive water in a furnace.

Now, about 30 years since modern condensing furnaces were introduced, most of those issues have been resolved.

Tips: Inspecting 90%+ Condensing Furnaces

Most home inspection standards require inspectors to open readily accessible panels and inspect the heating equipment, including vent systems, flues, chimneys and distribution systems. Inspectors must describe the energy source and the heating system. Here are my tips for inspecting a condensing furnace.

1. Outdoors, check the exhaust and intake PVC piping. It should be secure and not too close to windows or doors (or the ground, in climates where snow accumulates).

2. Indoors, save steps by dropping off your tool box near the furnace at the start of the inspection and identifying the exhaust and intake locations. Turn the furnace disconnect to off.

3. While inspecting the rest of the house, set the thermostat to “heat” as you walk by. If the weather is cold, the home may have cooled during the inspection and the furnace may try to start before you get back to the furnace disconnect switch. If you need to raise the temperature setting, raise it 10 degrees so you can easily remember where it was set originally.

4. Always use the normal controls to operate the furnace.

5. When back at the furnace, turn the furnace disconnect switch on and open the cover to observe the draft fan as the unit starts running. Listen for any excessive noise. A noisy or vibrating draft fan means the fan bearings may be failing.

6. Inspect the intake and exhaust piping. It should be solid and secure with no water leaks.

7. The burner should start a few minutes after the draft fan runs.

8. After the burner starts and runs for a few minutes, the blower/fan should start. Watch for excessive noise or vibration.

9. Reduce the temperature of the thermostat setting to cycle the unit off. If you did not raise the temperature setting just allow the home temperature to reach the original set point.

10. Look for any water leaks or corrosion—they indicate a potentially serious problem.

11. Open the fan chamber cover and check for leaks and dirt. Visually inspect the fan blades for dirt if possible.

12. Pull out the filter and check for dirt or defects.

13. If the unit is more than 10 to 15 years old, you may want to describe the unit as “at or near the end of its useful life.”

14. On a furnace with a zoned air distribution system, you are not required to check each zone—but it might be a good idea to do so anyway. Otherwise, note that you checked only one zone and the system should be evaluated by a furnace specialist.

15. Report excessive dirt, lack of maintenance, signs of leaks, vibrations, and noise. If any defects are visible, don’t just suggest maintenance service—suggest a full evaluation.

Get Client Involved

Explain the furnace operation to the client and describe the advantages of its efficiency. Condensing furnaces are a big plus for homes. If possible, have the customer watch as you start and run the furnace. This gives you a chance to explain the sequence of operation, startup, filter, air flow and any defects you identify.

To learn more, attend Tom’s technical presentations at educational sessions for home inspector groups. Tom will be presenting “Describe That Defect” and “The Practical Science Behind Great Home Inspection” at ASHI Inspection World® 2019 in San Diego. Tom can also provide his knowledge for your educational event; contact him at Tom@HTOYH.com.

Free Risk Management Online Course

Claims and Complaints: How to Stay Out of Trouble

Available Now

Presenter: David Brauner, Senior Insurance Broker OREP

David Brauner, Senior Broker at OREP, shares insights and advice gained over 25+ years of providing E&O insurance for inspectors, showing you how to protect yourself and your business. Watch Now!

About the Author

Tom Feiza has been a professional home inspector since 1992 and has a degree in engineering. Through HowToOperateYourHome.com, he provides high-quality marketing materials that help professional home inspectors boost their business.

Note: The Summer 2018 issue of Working RE Inspector mailed to over 20,000 home inspectors nationwide. OREP Insureds enjoy guaranteed delivery of each print magazine and many more benefits.