| > E&O/GL Insurance for Home Inspectors Competitive Rates, Broad Coverage, Free Risk Management, online inspection support for tough questions, discounts on education and more… Professional Coverage, Competitive Pricing Shop OREP today! |

Inspecting Electric Vehicle Charging Systems

by Mike Twitty

New technology brings additional educational challenges for home inspectors to consider. The popularity of electric vehicles (EV) in recent years has added another electrical system that inspectors will encounter in both new and existing homes and commercial settings.

A common opinion of many inspectors is that these systems are “out of scope” for a home inspection, and they should be disclaimed and referred to others for evaluation.

EV charging systems can often be the largest electrical load demand in a home, even exceeding HVAC and cooking equipment demands. The evaluation of the branch circuits/supplies for EV charging is no different from any other system and should be included in the home inspection. An experienced home inspector will already have the basic knowledge to properly inspect EV supplies, but some specific requirements and information must be learned.

There are three basic types of electric vehicle charging systems (Level 1, Level 2, and Level 3).

• Level 1 – Typically supplied with a standard 120–volt receptacle. While this is the most convenient way to charge electric cars, it is less practical because it may take a few days to fully charge the vehicle.

• Level 2 – Supplied by a 240 or 208–volt circuit. Charging time is greatly reduced with this supply. Overnight is usually sufficient to fully charge the vehicle. Level 2 charging systems are common in both residential and commercial installations.

• Level 3 – Normally supplied with a 480–volt circuit. These are known as “fast chargers” and are only found at commercial and public locations. A full charge can be completed in as little as 30 minutes.

Modern electric vehicles have onboard chargers (in the vehicle). These chargers convert the AC power to DC to charge the batteries. Level 1 and Level 2 systems use the vehicle’s onboard chargers. Level 3 chargers bypass the onboard chargers and directly supply the batteries with DC power.

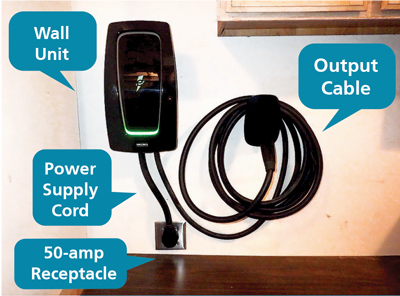

Figure 1: Wall Charger with Power Supplied from Receptacle; Image Courtesy of Jim Katen

Enlarged Image

Some Common Definitions/Terms

Now, let’s cover some terms and definitions for charging systems.

• Electric Vehicle Supply Equipment (EVSE) – This includes all supply conductors, receptacles, attachment plugs, power cords, and any other equipment used to transfer energy from the premises wiring to the vehicle.

• Electric Vehicle Power Export Equipment (EVPE) – This is also known as bidirectional power and is an option on some vehicles. It allows the vehicle battery to supply power to the electric grid or other external loads.

• Output Cable – This is the supply cable from a receptacle or wall mounted unit to the vehicle.

• Wall Charger/Wall Connector – The wall mounted unit that has input power supplied by either a receptacle or a hardwired circuit. The supply to the vehicle is the output cable described above. “Wall charger” is used by some manufacturers, but the term is technically incorrect because these units are not chargers. The charger is in the vehicle.

• Power Supply Cord – An assembly consisting of an attachment plug and flexible cord that connects equipment to a receptacle. This is a short cord that supplies power to a wall unit from a receptacle.

• Mobile Connector – The cord/cable that connects power from a receptacle directly to the vehicle. Adapters are available to connect this cord to both 120–volt and 240– volt receptacles.

• Vehicle Connector – This is the connector on a cord that attaches to the vehicle. The two standard configurations are the J1772 for most cars and the NACS that is proprietary for use only with Tesla vehicles.

Figure 2: NEMA 14–50 receptacle

Enlarged Image

Charging Connector Configurations

To complicate matters somewhat, there are two standard connector configurations for EV charging. The most common is the J1772, which is used by all manufacturers except Tesla. Tesla has their own connector design: the NACS connector. Having two different designs is not a new business concept and is often used by competitors. Consumers in the ‘70s and ‘80s were forced to decide between VHS or BETA formats for their video recording needs. Mac vs. Windows and iPhone/Android are similar format options that manage to coexist today.

The issue with EV charging is that many commercial/public charging stations are Tesla stations, and the charging cables will only fit Tesla vehicles. Adapters are being produced to allow some other vehicle types to use the Tesla stations. This of course, is at an additional cost for the consumer. Tesla does offer a universal level two wall connector that is equipped with a J1772 connector. Tesla also offers adapters to allow charging Tesla vehicles from non-Tesla equipment.

(story continues below)

(story continues)

Residential Charging Options

When it comes to residential charging options, there certainly is no lack of variety. Level 1 charging is simple. All that is needed is a standard 120–volt receptacle, the mobile connector power cord, and a 120–volt plug adapter. The power cord, 120–volt adapter, and 240–volt adapter are typically supplied by the vehicle manufacturer.

Several options are available for Level 2 charging. The two most common are a wall mounted connector unit or a 240–volt receptacle. Wall units can be hardwired or supplied from a receptacle with a power supply cord. A mobile connector cable directly connects power from a receptacle to the vehicle and no wall unit is needed. (See Figure 1.)

Most level two receptacles that are used are a 50-amp NEMA 14– 50. A 14–50 receptacle is normally known as a “range receptacle.” The supply conductors to a 14–50 consist of two ungrounded (hot) conductors, a neutral, and an equipment grounding conductor. A neutral is not used or needed for EV charging, so why is this receptacle the most common? Why not use a NEMA 6–50 receptacle that uses two hot conductors and an EGC? The answer is basically for convenience. A NEMA 14–50 is much more common in RV parks and campsites than a NEMA 6–50 receptacle. A 6–50 can be used, but an optional adapter usually must be purchased. The 14–50 adapter is often supplied by the manufacturer as standard equipment. Other options for level two receptacles are a NEMA 14–30 (4–wire/30 amp), a 6–30, or a 10–30 (both 3–wire/30 amp). These are normally used as dryer receptacles. An additional purchase of an adapter is needed for these receptacles as well. (See Figure 4.)

Figure 3: NEMA 3R Electrical Enclosure

Enlarged Image

IMPORTANT NOTE: 10–30 and 10–50 receptacles should not be used for new installations. They are non-grounded receptacles and are still produced only for the replacement of dryer and range receptacles in older homes. There are reports of some receptacles becoming damaged from overheating on EV circuits. Standard dryer and range receptacles are typically lighter duty and were not designed to handle the longer periods of heavy loads that are necessary for EV charging. Heavy duty industrial grade receptacles are available and should be used for EV charging. (See Figure 2.)

It is also important to note that the NEC requires all receptacles that supply power for EV charging are required to have GFCI protection for personnel. Hardwired wall units typically do not require GFCI protection unless specified by the manufacturer. GFCI protection is required for hardwired units installed outdoors that are rated 50 amps or less per NEC 210.8(F).

Figure 4: Tesla adapters

Enlarged Image

Some Key Differences in Charging Systems Options

Please note some key differences regarding the following EV charging systems.

• Direct Connection From a Receptacle to the Vehicle with a Mobile Connector/Adapter Combination: The cord and adapter are mobile equipment and can be transported with the vehicle to access charging supplies when traveling. They are compatible with 120–volt and 240–volt supplies when combined with the proper adapter.

• Adapter Load Limits: Most, if not all plug adapters/mobile connectors have built-in amperage load limits based on the circuit rating ranging from 12 amps for a NEMA 5–15 adapter to a maximum of 40 amps for a NEMA 14–50 adapter. (NOTE: The Tesla 14–50 adapter limits the maximum amps to 32.)

• Wall Connectors: Wall connector units are fixed in place. These are fed with 240–volt or 208–volt supplies. Although more powerful units are available up to 80 amps, many popular residential wall units have a maximum rating of 48 amps. When hardwired and the maximum amperage load is 48 amps, the minimum supply should be a 60–amp circuit. When the unit is plug fed from a 50–amp receptacle and circuit, the maximum load is 40 amps.

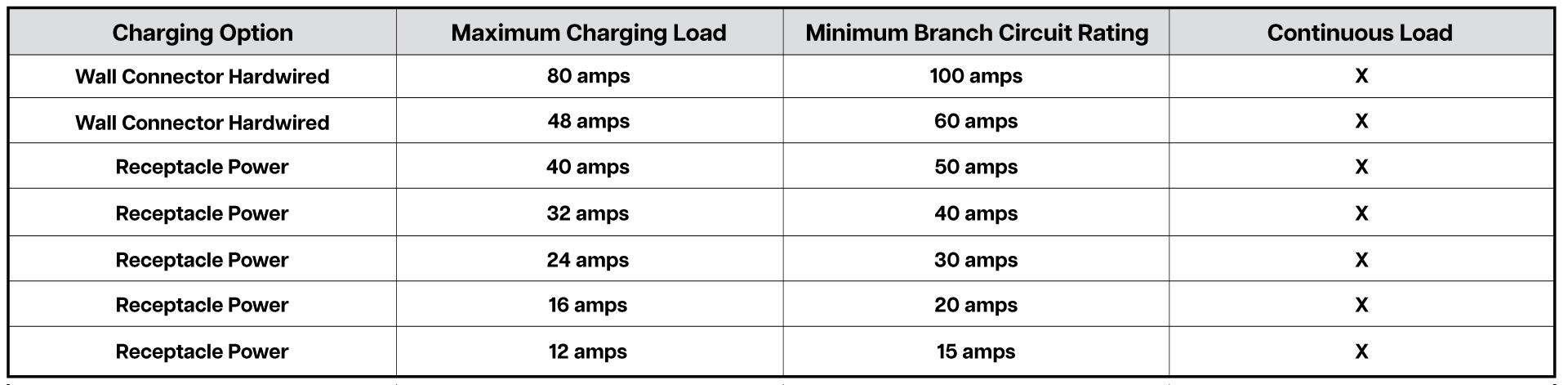

Figure 5: EV Circuit Requirements for Common Installations

Enlarged Image

All EV Charging Supplies are Considered Continuous Loads

Continuous loads are appliances or equipment that draw current for three hours or more. EV chargers fall into that category. When the appliance/equipment is a continuous load, the circuit conductors and overcurrent protection devices must be rated at a minimum of 125% of the circuit load. This is why when a charger supply pulls 48 amps, the circuit must be rated at 60 amps. (48 x 125% = 60) An 80-amp rated charging load would require a 100-amp circuit. (See Figure 5.)

The Inspector’s Role Evaluating These Systems

EV charging installations have become much more common in recent years. Inspectors see charging systems in homes on a regular basis. As mentioned earlier, some are choosing to disclaim these systems. Although access to internal components of supply equipment and vehicle chargers is not practical and certainly exceeds the responsibility of the home inspector, evaluating the branch circuits that supply the equipment is no different than that for any other appliance. Learning to evaluate all of the varied power supply options for EV charging is a necessary skill for home inspectors.

Recommendations for Inspection (Basic)

Here are some recommendations for basic inspections.

• When possible, get wall connector data/ratings.

• Confirm proper breaker and conductor size.

• Confirm the branch circuit rating is a minimum of 125% of the rated load.

• Confirm GFCI protection for all supply receptacles and outdoor equipment.

• Confirm weather-rated enclosures for outdoor installations.

• Inspect the condition of all visible cords, receptacles, connectors, and wiring.

• Include a comment in the report detailing any equipment that was not inspected and recommendations for more evaluation when needed.

Advanced Inspection Recommendations (Optional)

NOTE: The following inspection recommendations should only be done by persons with advanced electrical training and experience with EV systems.

• Most equipment manufacturers specify “copper conductors only.” Confirm compliance when possible.

• Report EVPE bidirectional power supplies when present. Evaluation of these supplies can require advanced knowledge. The best practice is to report that it is present and to recommend further evaluation by a qualified person.

• Faceplates for wall units can be removed to inspect for loose terminal connections or internal damage.

• Load calculation. EV charging loads are often the highest power demand in a home. Load calculations are performed when the home is built to properly size the electrical service. When an EV system is added, the service capacity can be exceeded. Recommend having a load calculation when Level 2 systems are installed.

Limitations of Inspections

Some limitations of inspections include:

• Data/rating information is not available for equipment.

• Circuits are not labeled in the electrical panel.

• Physical access is not possible due to storage items, vehicle obstruction, etc.

EV Charging Requirements in the National Electric Code

The specific requirements for electric vehicle charging systems are located in article 625 of the NEC. Article 625 was first added in the 1996 edition. Revisions have been made in every edition up to and including the 2023 edition.

Historical Context

Before Henry Ford revolutionized the automobile industry with mass production of gasoline powered cars in 1913, electric vehicles were the more predominant style. Although the NEC did not dedicate an article relating to electric vehicles until the 1996 edition, specific requirements were included in other articles dating back to the early to mid-nineteen hundreds.

Special thanks to Jim Katen for his help in providing information and edits for the article.

About the Author

Mike Twitty retired from a 17-year home inspection career in 2021. He is a licensed electrician and an ICC certified electrical code compliance inspector for residential and commercial installations. Mike currently stays busy providing continuing education for home inspectors focusing specifically on electrical subjects. He can be reached via email at: mtwitty2@hotmail.com.

Published by OREP Insurance Services, LLC. Calif. License #0K99465