|

> E&O/GL Insurance for Home Inspectors Competitive Rates, Broad Coverage, Free Risk Management, online inspection support for tough questions, discounts on education and more… Professional Coverage, Competitive Pricing Shop OREP today! |

Dryer Venting: Safety Tips

by Todd Peach, InOvate Technologies

The responsibility of inspecting a house can be daunting, to say the least. There are many rules that come into play. Some defects can be benign while some present an immediate safety hazard. Then there are the dynamics between the home seller, buyer and agents. Everyone wants to pull you in a different direction while, as an inspector, you must keep a keen eye on safety.

One of the most important things stressed during inspection training is that inspectors are safety inspectors, not code-enforcers. This is an important distinction because so much is riding on your ability to spot trouble areas. Electrical, plumbing, mechanical, deck and hand railings, and their myriad variations create plenty of areas for concern. Today, let’s focus on an area of the house that often gets too little attention—dryers.

Laundry Room Can Be Dangerous

Every year, according to National Fire Protection Agency

(NFPA), there are more than 14,000 dryer fires reported. In your travels, you’ve likely come across evidence of small fires that homeowners didn’t even know they had (and could become disasters), so the actual numbers are probably more daunting. The importance of properly configured and maintained dryers and dryer exhaust systems can hardly be overstated. And what about efficiency? If there are problems with the exhaust, drying times can grow into hours, which wastes energy, not to mention the extra wear and tear on the appliance and the clothes. An efficient, well designed exhaust system can let the dryer work at peak operating levels.

Things to Check

If a home has a gas dryer, the first thing to check for is the smell of a gas leak, which requires immediate action. Then, check for lint leaking out of the dryer or around the dryer transition hose. Lint blowback into the heating element can create a very dangerous situation. Then there are questions for the homeowner: has the dryer been taking too long to finish? Does the exterior of the dryer become hot to the touch toward the end of the cycle? Is the lint trap being cleaned?

Importance of the Transition Hose

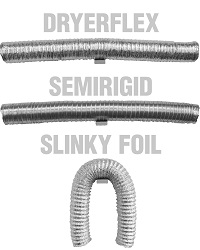

Now it’s time to look closely behind the dryer. The first thing to keep an eye out for is plastic. If there is a plastic connector or plastic transition hose, this should be noted. It is a fire hazard. Then it gets a little tricky. There are some dangerous “slinky foil” transition hoses that might look a little like a UL 2158A listed transition hose, but they are not. To the touch, the difference can be obvious. A UL 2158A flexible hose can be adjusted (try prodding it to keep from pulling out the appliance), but it takes a little work to move it around. Slinky foil just flips around and is, well…slinky. Watch for a newcomer in UL 2158A listed flexible transition hose called DryerFlex™ (dryerflex.com). DryerFlex is more efficient than “slinky foil,” resists flame spread, and it is stronger than semi-rigid. Which brings us full circle to the old, approved way of connecting the dryer: semi-rigid hose can be UL 2158A, but it is hard to work with and crushes easily. While it does not represent the serious fire hazard of plastic or slinky, be sure to watch that it is not crushed behind the dryer. If it is, lint blowback into the dryer element can create a hazard.

Duct Run Length Can Be a Major Issue

In some cases, it can be obvious that the exhaust system only runs a few feet to get from the back of the dryer to the exterior of the building. The rule of thumb is the shorter the better. This is because even straight pipe creates airflow resistance, and a long run can keep lint from escaping. Once again, you can end up with lint blowback into the dryer’s element. Most building code requires a run of 35 feet or less, including five-foot penalties for each standard elbow (long turn elbows are the exception). Some dryer manufacturers allow longer runs, so it is a good idea to check the dryer’s manual as well. If the run is too long, it is time to recommend a re-route or the addition of long turn elbows if there are too many standard elbows.

(story continues below)

Understanding the Exit Port

Now that you’ve found the system to be in good shape, there is one more issue you’ll want to address: the external vent. You’ll be surprised how many vents 1) have screens, 2) are too small of a port or 3) have no damper. All of these are prohibited by code for venting a dryer and need to be replaced. Surprisingly, a bad termination can be responsible for 90% or more of airflow restriction.

As an inspector, spotting and successfully diagnosing danger points is a critical job. Take the time to learn the difference in transition hose options so a correct assessment can be made, and the proper recommendation given. For latest information on transition duct and exhaust system efficiency visit https://dryerflex.com.

Free Risk Management Online Course Claims and Complaints: How to Stay Out of Trouble

Available Now

Presenter: David Brauner, Senior Insurance Broker OREP

David Brauner, Senior Broker at OREP, shares insights and advice gained over 25+ years of providing E&O insurance for inspectors, showing you how to protect yourself and your business. Watch Now!

About the Author

Todd Peach has over 14 years’ experience developing new products for venting efficiency and safety and has extensive knowledge of building code requirements. Peach is the Vice President of Marketing for InOvate Technologies, which works to improve upon and minimize the dangers associated with this important system.

Note: The Fall 2019 issue of Working RE Inspector is mailing now to over 25,000 home inspectors nationwide. OREP Insureds enjoy guaranteed delivery of each print magazine and many more benefits.

by Ron Greene

Secondary lint traps

-Ron Greene

goldeneaglehs@gmail.com